How laser cutting works

Laser cutting is an extremely common tool across many industries, however despite its popularity it remains somewhat of a new technology. The first working laser dates to the 1960’s and once the capabilities and accuracy of the tool became apparent, laser cutting has continued to grow and develop.

Laser cutting is now becoming somewhat of a standard tool in many industries because of the significant benefits it provides. A single laser beam is now powerful enough to cut through wood, plastics and metals and as such, laser cutting has helped to revolutionise much of the manufacturing industry.

So how does laser cutting work?

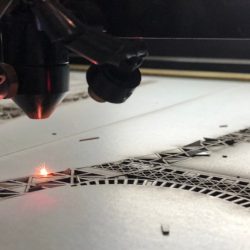

In the simplest of terms, a high-energy infra-red laser light beam is directed onto the chosen material. A focusing lens is used to concentrate all of the energy onto a pin-point, causing rapid localised melting and partial vaporisation of the material. A gas such as oxygen or nitrogen is then directed through a nozzle to expel the molten material.

The position of the laser beam is precisely controlled by computer program driving the CNC machine, which adjusts the power of the laser beam to ensure that that the laser power is optimised for the current cutting speed and material.

Cross technology communication

Laser cutting technology can be combined with other industrial technologies such as CAD/CAM software and has greatly helped to speed up manufacturing processes. This means that many processes can now be automated whereas before they would have had to be done by hand. This technology communication reduces the manpower required and production times for any project. The combination of technology delivers a faster turnaround time for production time scales and also helps to make the final product more affordable.

Extreme accuracy

Laser cutting is know for its accuracy as all of the power is focused into a very fine beam. When combined with other technologies, it can be used to cut materials to exact specifications time and time again. Such is the accuracy of laser cutting that it can also be used in applications that require accuracy to less than a millimetre.

As advanced as laser cutting technology may seem, it is still in its infancy. As our technology develops in the industry, we will be able to produce ever more powerful lasers with greater cutting power and even greater accuracy.

Contact Yorkshire Laser today and find out how we can help bring your project ideas to life.