The process of laser cutting

As the name may suggest, laser cutting is the process of cutting a material using a laser beam. This process can be done to either trim down a material or to help cut it into complex shapes that more conventional drills would struggle with. With the developments of modern technology, a single laser beam is now powerful enough to cut through wood, plastics and metals and as such, laser cutting has helped to revolutionise much of the manufacturing industry.

What is laser cutting?

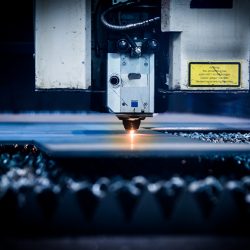

Laser cutting is the process of a high-energy infra-red laser light beam being directed onto the chosen material. The beam pierces the material with a hole at the edge, and then the beam is continued along from there, essentially melting the material away where necessary. This means that the laser can easily cut light materials such as cloth through to tougher materials such as metals and gemstones.

The position of the laser beam is precisely controlled by computer program driving the CNC machine, which adjusts the power of the laser beam to ensure that that the laser power is optimised for the current cutting speed and material.

So, how does laser cutting work?

In the simplest of terms, laser cutting works by having a focused and precise laser beam directed through the chosen material, delivering an accurate cut and smooth finish. The laser essentially melts the material in its set path, almost melting away the material rather than cutting it.

Typically, laser cutting uses either a pulsed beam or a continuous wave beam. The pulse beam is delivered in short bursts while the continuous wave beam works as it suggests in a continuous movement. The beam can be controlled in terms of intensity, length and temperature depending on the material being manipulated.

The position of the laser beam is precisely controlled by computer program driving the CNC machine, which adjusts the power of the laser beam to ensure that that the laser power is optimised for the current cutting speed and material. Laser cutting is a highly accurate process, thanks to this high level of control that you are offered. Thanks to this, slits with a width as small as 0.1mm can be achieved when using the process.

Increasing in power

As our technologies have advanced, we have found ways to develop increasingly powerful lasers, and many of these have found their way into a broad range of industries. Laser cutting is now becoming somewhat of a standard tool in many industries because of the benefits it provides. A single laser beam is now powerful enough to cut through wood, plastics and even metals. As such, laser cutting has helped to revolutionise much of the manufacturing industry.

Lasers are used to help in heavy industry, and also in applications where dexterity and precision is required. Here at Yorkshire Laser & Fabrication, we supply lasers to a wide range of industries throughout the region and the country.

With technology constantly advancing, it is finding itself in a wider range of applications more and more as time moves on. Here’s a look at some of the common applications that our lasers are used for today.